Omnia PX

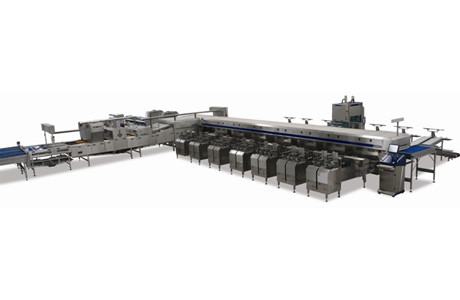

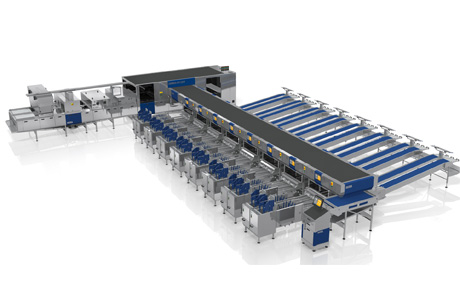

With the Omnia PX series, Moba sets a new standard within the industry regarding three important goals for egg producers.

Product Information

It is our firm belief that customers benefit the most from their investment in equipment if packaging costs, labor costs and losses throughout the process are significantly reduced. The Omnia PX sets the standard within the industry regarding these points. It achieves top efficiency with 2% more Grade A eggs and complies with the highest standards in hygiene and food safety.

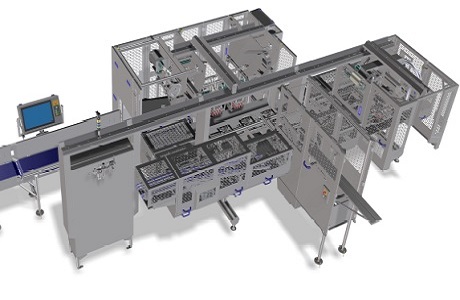

With the Omnia PX series, you can expect everything the Omnia FT has to offer with additional control and hygiene functions throughout the machine. For example, all the machine parts that handle eggs can be disinfected with UV and the machinery is equipped with touch screens above the packing lanes for quick product changes and fewer operator errors.

Due to the latest innovations, the Omnia PX also offers an extremely broad range of capacities, ranging from 45,000 eggs/hour to 255,000 eggs/hour.

And now Moba can offer AI in vision weighing, egg inspection, and crack detection on both the Omnia PX530 and PX700. This PX+ offers a comprehensive solution that eliminates the need for direct egg contact, provides easy operation, simplifies cleaning procedures, and requires minimal maintenance. This PX+ is only available in a limited region.

Specifications

Swipe this table side to side to view all specifications

| Technical Data | PX125 | PX180 | PX250 | PX350 | PX530 | PX530+ | PX700 | PX700+ |

|---|---|---|---|---|---|---|---|---|

| Function | Grading and packing eggs on weight and/or defects | |||||||

| Capacity (eggs/hour) | 45,000 | 64,000 | 90,000 | 127,000 | 191,000 | 191,000 | 255,000 | 255,000 |

| Capacity (cases/hour) | 125 | 180 | 250 | 350 | 530 | 530 | 700 | 700 |

| Tracks | 2 | 2 | 4 | 4 | 6 | 6 | 8 | 8 |

| Infeed rows | 6 | 6 | 12 | 12 | 18 | 18 | 24 | 24 |

| Min. no. packing lanes | 6 | 8 | 8 | 10 | 14 | 14 | 18 | 18 |

| Max no. packing lanes | 12 | 16 | 16 | 24 | 24 | 24 | 32 | 32 |

| Optional features | ||||||||

| Egg Inspector (leaker + dirt) | o | o | o | o | o | o | o | o |

| Shell Inspector (crack + shell strength) | o | o | o | o | o | o | o | o |

| Blood Detector | o | o | o | o | o | o | o | o |

| Vision weighing | o | o | ||||||

| Main hygienic features | ||||||||

| Downwash infeed system | + | + | + | + | + | + | + | + |

| Downwash packing lanes | + | + | + | + | + | + | + | + |

| Cleaning in place - infeed | + | + | + | + | + | + | + | + |

| Cleaning in place - weighing system | + | + | + | + | + | + | + | + |

| Cleaning in place - tracks | + | + | + | + | + | + | + | + |

| UV on egg-carrier tracks | + | + | + | + | + | + | + | + |

Downloads

Building Your Sustainable Egg Future

Find the Egg Grading System That Fits Your Operation

We provide customers with complete egg grading solutions. We will help you by choosing the right system for the required egg grading job.

Related solutions